Well I've recently delved into making liquor after wanting to tackle this for sometime. This is a how-to, to a certain degree but also a bit a documentation of my first attempt at it. But this will lay out the basics as this is a fairly rudimentary setup and you can tweak, twaddle and use what you have on hand to achieve the same basic result which is...booze.

You are going to want to start with a fermentation vessel.

I took two paint buckets washed thoroughly and drilled on hole in the lid with a 3/8s bit. Ran 3/8s tubing out of that hole into an airlock which was made out of an old grape juice bottle. Drilled two holes in that one for the tubing and one for co2 to escape from. Put water in the airlock and put the tubing just under the water line. This allows co2 to escape from your bucket without allowing dust, bacteria, bugs etc. to get in.

049 by TyMoe, on Flickr

Basic Recipe a "Sugar Wash"

6 Gallons of water

7 lbs of sugar

1/2 cup of baker's yeast

1 cup of Gerber dry baby food (this is to provide the yeast nutrients that are not available in refined sugar.)

Juice of two lemons

I only had 5 gallon buckets and for the sake of simply halving this recipe I split it into two 3 gallon batches in two different 5 gallon buckets.

Pour your sugar into your fermentation vessel. Dissolve with your 6 gallons of warm water, lemon juice and baby food. Let this cool until it's in the 90 degree temperature range. Better colder than too hot as the yeast will die. Once cooled drop your yeast in, "pitching" your yeast. Let these guys hang out for 15-20 minutes on top and then give it all a good stir and put your lid on.

Let all this ferment for 4-5 days and you should stop seeing bubbles in the airlock.

Now once this is done you want to get all of that sweet sweet liquor out of there. For this you need a still. Mine consists of this - A cheap ass old 12 quart stock pot with lid with two 3/8s inch holes drilled into the top. One hole is for a thermometer (not required) and the other for the "lyne arm" or copper tubing that is going to my condenser.

078 by TyMoe, on Flickr

The thermometer is stuck through the hole I drilled into a 1/2 inch cork and crammed both of those in and put a little bit of silicone on the top to keep the vapors in.

The lyne arm is a 10 foot section of 3/8s inch copper tubing that as one piece is the lyne arm and the cooling coil. I started by making the coil. This takes a little bit of finesse as you can easily kink this tubing making it nonfunctional.

You want all the winds in your coil to be sloping down so vapors don't condense and pool up inside of it.

The coil resides in a 5 gallon bucket. Spigot coming out of the bottom, coil in the bucket, and the lyne arm exiting the top of the bucket into the boiler. Silicon at least the spigot exit to make it water tight because we are going to be filling the bucket with water to cool the alcohol vapors back into a liquid.

063 by TyMoe, on Flickr

Once all of this is constructed and setup do an all water run to make sure everything is functioning. You don't want to spend all this time fermenting and end up wasting your time effort and ingredients because there is a leak somewhere.

To seal your pot lid and the where the lyne arm meets the lid of the boiler all you need is some self rising flour and water. Mix both together at a 1 to 3 ration of water to flour until you have a paste that juuust sticks your hands but is still workable. Now roll this out into sections that are about the size of a sharpie marker and place them on the lip of the pot to form a seal once the lid is placed on top. I used little vice grip pliers that I was able to "procure" from one of the big box hardware stores but the small black binder clips work great too to keep everything in place.

Also, form a seal around the lyne arm and the lid of the pot.

The flour once hit by steam forms a great seal as it expands and more or less becomes an air tight dumpling

Fill your boiler and condenser up with water and letter rip

http://blog.fabshophop.com/blog/wp-content/uploads/2009/11/BindersClipN00004.jpg

Once everything is working and you have now steam cleaned your new still. Siphon all of your mash into your boiler leaving all the yeast at the bottom. Bring it up to heat moderately. On the electric range I've been using it's around 6 or 7 on the dial.

The first alcohol that will be coming out is reffered to as "the heads". It's nasty stuff consisting of acetone, methanol and other low alcohols. For a batch this size throw out about the first 50-100 ml. You can sample it and it's pretty obvious you don't want it.

Now comes "the hearts" the good stuff. I go by the smell and taste of it. I also use a teaspoon and lighter. I catch some in a teaspoon turn off the light and see how easily it ignites. Once it's not so easy to light and the liquor starts tasting watery your in "the tails". Save these as you can throw them in with your next batch and get the goods out of it.

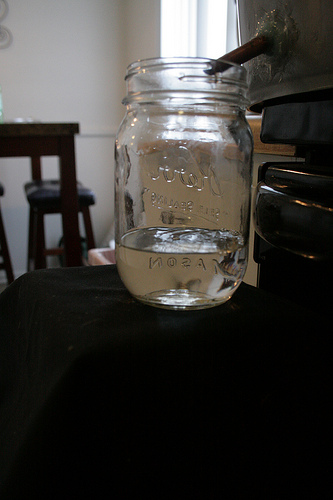

059 by TyMoe, on Flickr

060 by TyMoe, on Flickr

I got about 3 pints of pretty damn good liquor out of this setup. So there yuh go. There are much more refined ways of making it and I'm not claiming to be a master distiller and I'm sure I left specifics out but this is a way that I've been getting drunk.

070 by TyMoe, on Flickr

073 by TyMoe, on Flickr

Bottoms up! - Tbone

You are going to want to start with a fermentation vessel.

I took two paint buckets washed thoroughly and drilled on hole in the lid with a 3/8s bit. Ran 3/8s tubing out of that hole into an airlock which was made out of an old grape juice bottle. Drilled two holes in that one for the tubing and one for co2 to escape from. Put water in the airlock and put the tubing just under the water line. This allows co2 to escape from your bucket without allowing dust, bacteria, bugs etc. to get in.

049 by TyMoe, on Flickr

Basic Recipe a "Sugar Wash"

6 Gallons of water

7 lbs of sugar

1/2 cup of baker's yeast

1 cup of Gerber dry baby food (this is to provide the yeast nutrients that are not available in refined sugar.)

Juice of two lemons

I only had 5 gallon buckets and for the sake of simply halving this recipe I split it into two 3 gallon batches in two different 5 gallon buckets.

Pour your sugar into your fermentation vessel. Dissolve with your 6 gallons of warm water, lemon juice and baby food. Let this cool until it's in the 90 degree temperature range. Better colder than too hot as the yeast will die. Once cooled drop your yeast in, "pitching" your yeast. Let these guys hang out for 15-20 minutes on top and then give it all a good stir and put your lid on.

Let all this ferment for 4-5 days and you should stop seeing bubbles in the airlock.

Now once this is done you want to get all of that sweet sweet liquor out of there. For this you need a still. Mine consists of this - A cheap ass old 12 quart stock pot with lid with two 3/8s inch holes drilled into the top. One hole is for a thermometer (not required) and the other for the "lyne arm" or copper tubing that is going to my condenser.

078 by TyMoe, on Flickr

The thermometer is stuck through the hole I drilled into a 1/2 inch cork and crammed both of those in and put a little bit of silicone on the top to keep the vapors in.

The lyne arm is a 10 foot section of 3/8s inch copper tubing that as one piece is the lyne arm and the cooling coil. I started by making the coil. This takes a little bit of finesse as you can easily kink this tubing making it nonfunctional.

You want all the winds in your coil to be sloping down so vapors don't condense and pool up inside of it.

The coil resides in a 5 gallon bucket. Spigot coming out of the bottom, coil in the bucket, and the lyne arm exiting the top of the bucket into the boiler. Silicon at least the spigot exit to make it water tight because we are going to be filling the bucket with water to cool the alcohol vapors back into a liquid.

063 by TyMoe, on Flickr

Once all of this is constructed and setup do an all water run to make sure everything is functioning. You don't want to spend all this time fermenting and end up wasting your time effort and ingredients because there is a leak somewhere.

To seal your pot lid and the where the lyne arm meets the lid of the boiler all you need is some self rising flour and water. Mix both together at a 1 to 3 ration of water to flour until you have a paste that juuust sticks your hands but is still workable. Now roll this out into sections that are about the size of a sharpie marker and place them on the lip of the pot to form a seal once the lid is placed on top. I used little vice grip pliers that I was able to "procure" from one of the big box hardware stores but the small black binder clips work great too to keep everything in place.

Also, form a seal around the lyne arm and the lid of the pot.

The flour once hit by steam forms a great seal as it expands and more or less becomes an air tight dumpling

Fill your boiler and condenser up with water and letter rip

http://blog.fabshophop.com/blog/wp-content/uploads/2009/11/BindersClipN00004.jpg

Once everything is working and you have now steam cleaned your new still. Siphon all of your mash into your boiler leaving all the yeast at the bottom. Bring it up to heat moderately. On the electric range I've been using it's around 6 or 7 on the dial.

The first alcohol that will be coming out is reffered to as "the heads". It's nasty stuff consisting of acetone, methanol and other low alcohols. For a batch this size throw out about the first 50-100 ml. You can sample it and it's pretty obvious you don't want it.

Now comes "the hearts" the good stuff. I go by the smell and taste of it. I also use a teaspoon and lighter. I catch some in a teaspoon turn off the light and see how easily it ignites. Once it's not so easy to light and the liquor starts tasting watery your in "the tails". Save these as you can throw them in with your next batch and get the goods out of it.

059 by TyMoe, on Flickr

060 by TyMoe, on Flickr

I got about 3 pints of pretty damn good liquor out of this setup. So there yuh go. There are much more refined ways of making it and I'm not claiming to be a master distiller and I'm sure I left specifics out but this is a way that I've been getting drunk.

070 by TyMoe, on Flickr

073 by TyMoe, on Flickr

Bottoms up! - Tbone